Today's mission was to finish installing the brake system. Sadly, it didn't quite work out like I planned. I started out by installing all the AN822 elbow fittings in the four brake master cylinders, using plenty of Bakerseal to lube and seal the pipe threads:

Unfortunately, I managed to twist one of the fittings off inside a cylinder, thus ruining it. Arrgh! Since I'm trying to keep this site PG-13 I won't relate what I said when this happened. Use your imagination. On Monday I'll be calling Van's to order a new $78 brake cylinder, I guess. Today's lesson: aluminum pipe threads won't take a lot of torque, even if you only need "just a little more" to get the fitting clocked the way you want it. Grrr.

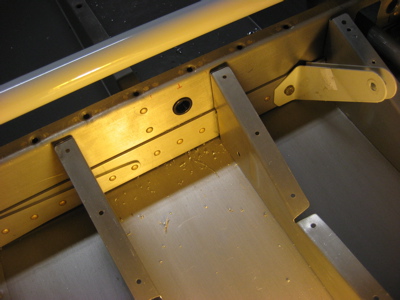

I got the parkng brake valve installed in its home on the firewall:

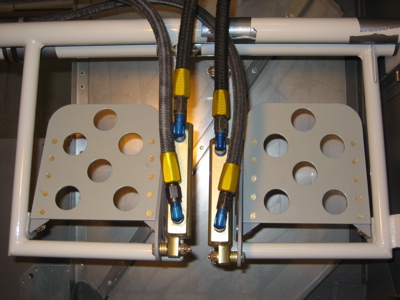

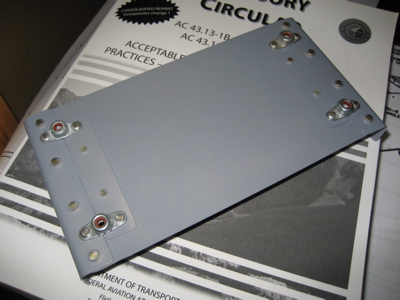

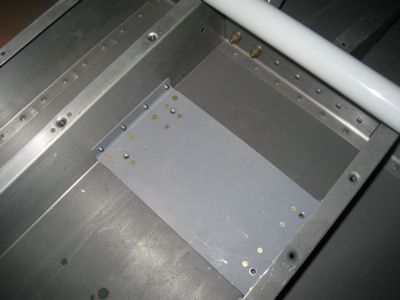

Here's how I ended up routing the crossover hoses from the passenger side to the pilot's side. Adel clamps secure each hose to its respective torque tube – they are splayed out and offset so they won't interfere with each other when full right rudder is used. Then at the F-6118 rudder pedal brace, I fabricated a small plate that will be riveted on to cover two of the lightening holes. When the pedals are moved, the hoses pivot inside a pair of SB625-8 snap bushings in the plate. I kind of wish I hadn't cut the optional lightening holes in the pedal brace, because it would have given me better options for more direct routing of the hoses. These "anti lightening holes" (weightening holes?) seem like they'll work okay though. If you're reading this and you haven't made your pedal brace yet, wait to cut holes in it until you're sure about how your brake lines are going to run.

Second major frustration of the day: the hoses from the pilot's side brake cylinders to the parking brake valve are too short! I think I must have had the valve in a different location when I originally measured to see what hose lengths I'd need. Now that the valve is permanently mounted, the left side hose gets stretched when full left pedal is used, and the right side hose just doesn't reach at all. Grrr. On Monday I'll have to order a new pair of hoses – it looks like one 17" and one 18" will do the trick.

Other than the busted master cylinder, things seem to be mostly okay on the right side. The clamping arrangement in use on this side means the crossover hoses don't need to flex or pivot on this end when the pedals are moved. I think the hoses from the brake reservoir to the passenger pedals are going to work as well, but if they don't I can always remake them myself since they're low-pressure only.

So in conclusion, I didn't get to finish this piece of the project today like I planned, and it was a pretty expensive day in terms of parts that need to be replaced. Grrr.