I made two bushings out of 3/8" OD 0.058" wall steel tube, each about two and a half inches long. 1/4" bolts fit nicely inside.

I used the bushings and bolts to temporarily attach the mount to the firewall, using the pre-drilled 1/4" holes. I used the two upper corners for this, but I think you could do it with whichever pair of holes lines up best.

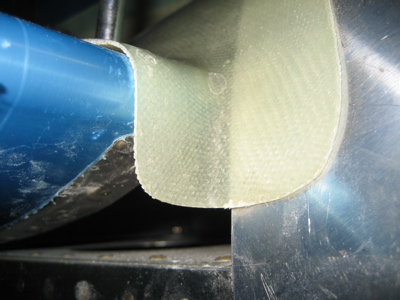

Immediately it became apparent that I needed to remove some of the firewall flange at the lower corners where the gear sockets are. Checkoway has a better photo on his site. I used a grinding thingy in my Dremel to make the rough shape, then filed and scotchbrited it smooth. I think I'll have to come back and open this up further when I go to insert the gear legs, but right now it's trimmed enough to at least get the engine mount onto the firewall.

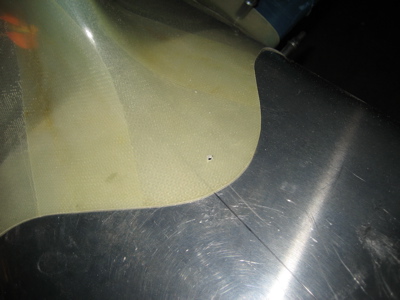

One hole at a time, I drilled up to just a bit less than 3/8" using a U-size drill bit (0.368") then reamed up to 0.375". At the two lower center bolt locations, the mount was spaced away from the firewall a bit, so I made some spacers out of alclad scraps. I think I used 0.032" for one and 0.016" for the other.

After the holes were drilled, I made the spacers all round and pretty:

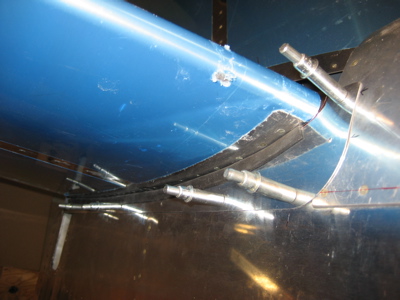

Huzzah, the engine mount is on the fuselage. I didn't torque or safety the bolts, as I'm sure I'll have it on and off a few times before it's bolted on for good.

Yep, it's plenty strong.