The plans have you pass the engine control cables through the firewall using plastic snap bushings, but I since I wanted something a lot more chafe- and fire-resistant I decided to use metal "eyeball" swivel fittings. These come in two basic varieties – one where the halves of the ball are retained only by a twist-on locking ring, and one where there are six screws holding everything in place. I've seen instances where the no-screw variety has come apart unexpectedly, so I decided to go with the seven-hole eyeballs despite the fact that they are a little more work to install.

Also, after the big deal I made about aluminum versus steel on the firewall, I was happy to see that the seven-hole eyeballs are available in steel as well as aluminum. However, after further investigation it became obvious that the steel flavor can only be enlarged up to 0.26" because of they way they're built (look at the photo on Van's website and you'll see why). The engine control cables are more like 3/8", so the steel eyeballs are out. Oh well, maybe since the aluminum balls are solid chunks of metal, not hollow, it'll take them longer to melt…

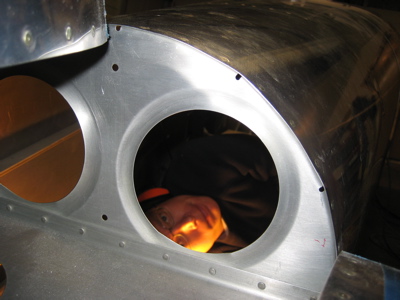

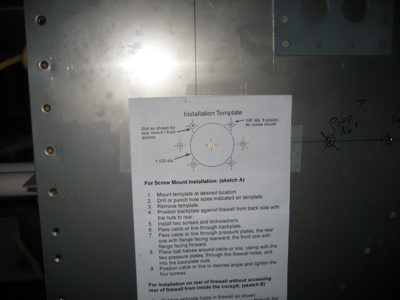

Anyway, I received three of the seven-hole eyeballs in my latest Aircraft Spruce order, so I decided to try installing one tonight. First you use a punch to mark the hole locations using the handy template they send you. I put my shop light on the other side of the firewall to help me line up the center pilot hole.

After drilling the screw holes, I used a Greenlee knockout punch to make the 1 1/8" center hole.

Those punches are expensive (on the order of fifty bucks per size) but they make pretty nice holes that need minimal deburring.

Here's the finished product. Four of the screws hold the ball retainer ring to the firewall, and the other two screws keep the nut ring on the back in place.

Viewed from the cabin side of the firewall, you can see the nut ring. Simple as can be.

I'm pretty happy with these fittings – I think they should work just fine. It should be easy later on to adjust them without needing to find somebody to help me put a wrench on both sides of the firewall. It's like two more minutes per eyeball to install, but the payoff in terms of secure attachment and ease of adjustment seems worth it to me.