Mary had to work today, so contrary to her orders I spent some time in the cold garage warm and healthful airplane workshop. I riveted the firewall recess in place for good, which let me check off another longstanding to-do item.

For this riveting task I used my new tungsten bucking bar. Man, I wish I'd bought this thing a long time ago. It's really a night and day difference compared to the steel bars I have, because it's made of such dense material. It's so hardcore that you can practically just wave it in the general direction of the rivets and they buck themselves out sheer terror. It was not inexpensive, but it really is an excellent tool.

Believe it or not, the steel bar on the left actually weighs less than the bar on the right. Can you guess why? That's right, it's because the one on the right is made of delicious tungsten.

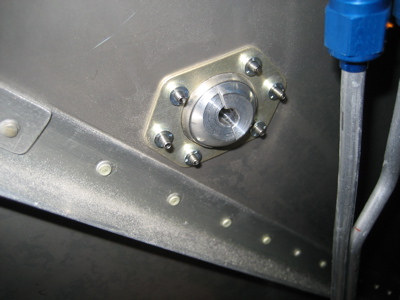

Then I bolted on the engine mount and torqued all the nuts.

I put the cotter pins in too, which practically guarantees that I'll find a reason to take the engine mount back off the fuselage next week.