Today stated off well but ended poorly…

I wanted to use a restrictor fitting for the connection to the manifold pressure hose, to keep the #3 cylinder from running too lean if the hose breaks. But, Van's only sells a 45-degree restrictor which won't fit on my engine. I had to make my own straight restrictor by filling an AN816 fitting with JB Weld, waiting a day for it to cure, and then drilling a #60 hole through it. Turned out great:

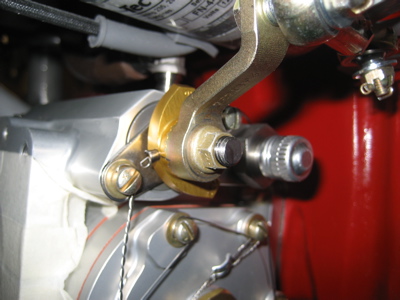

Installed in the port on the #3 cylinder:

The manifold pressure hose attaches to the restrictor fitting, then sort of loops inward:

It's attached to the engine mount with adel clamps, and passes through a fitting I installed in the firewall near the brake fluid reservoir.

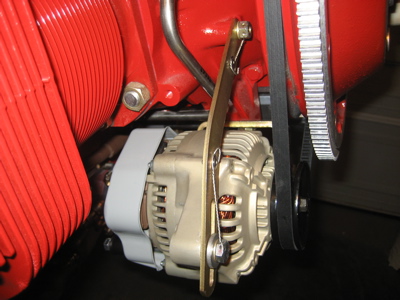

The hose that goes between the firewall and the fuel pump inlet is a tight fit, but it works. In this photo I'm using a bungee cord to teach the hose to follow a curve that keeps it away from the engine mount. A couple hours like that and it kept the right shape on its own.

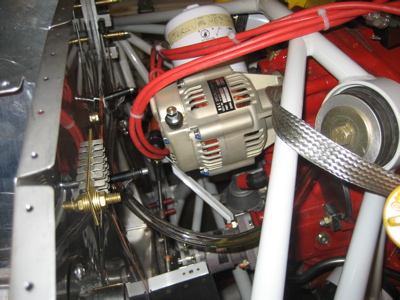

The oil pressure hose exits the right side of the accessory case, loops around to the left, and is secured to the top of the firewall with adel clamps.

The oil pressure hose enters the transducer manifold (top of photo), as does the fuel pressure hose (bottom). Eventually there will be pressure transducers screwed into the manifold, and the unused holes will be plugged.

The fuel pressure hose runs down to a tee on the outlet of the fuel pump (brown hose in center of photo). Also visible in the background is the fuel pump overflow hose, which runs down to the bottom of the firewall.

I have a policy that any hose that carries pressure should be professionally made and tested, but since the fuel pump drain hose doesn't carry any pressure and should rarely even have any fuel in it, I decided to make that one myself. This is Aeroquip 303 hose, using the recommended mandrel for assembly. It's a pain to do properly – I'm glad to leave making the proper hoses to the pros.

Of course, the plans call for the fuel pump overflow hose to be made from plastic tubing, but I thought that was cheesy. My hose is a little heavier but at least it won't melt/crack/etc. The hose runs down to an AN837 fitting that's adel-clamped to the engine mount, and thence a length of aluminum carries the fuel overboard and out the back of the cowling. I drilled out one of the rivets on the firewall flange and used it for a screw and clamp that secures the tubing.

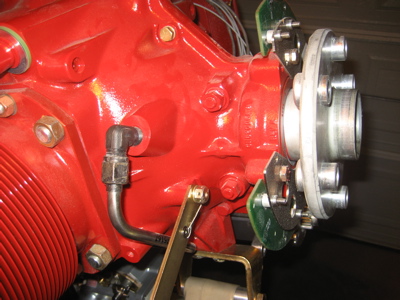

Here's where it all went off the tracks… while installing the very last fitting, the upper one for the fuel pump drain, I accidentally cracked the fuel pump housing:

Another photo with different light. I guess it doesn't take very much torque on a steel fitting to ruin a thin cast-aluminum housing.

After stewing about it for a while, I decided that the fuel pump has to come off to be rebuilt. That meant I had to take off most of the hoses I'd just spent hours installing. I also had to take off the magneto and loosen the prop governor cable bracket just to be able to get at the fuel pump bolts. Nothing on the engine is easy to work on!

After a couple hours of bad language, the fuel pump is now removed from the engine. Hopefully repairing or replacing it won't be too expensive.

I also had to mow the hateful lawn, and the new Indiana Jones movie was not very good, and now I have a headache, so overall this day has been kind of a dud.