Time to install the parking brake cable… I actually had to remove the parking brake valve from the airplane, since I quickly discovered that the lever will hit the hose fitting once the control cable nut is installed. Good thing I used nutplates on the valve bracket – at least it was easy to remove.

The lever is joggled a bit, but I had to bend it further to keep it from hanging up. Seems like kind of a silly design to me.

I bought a locking cable and drilled a hole for it underneath the transponder. I briefly toyed with the idea of somehow hanging it off the side of the throttle quadrant, but this way is much easier.

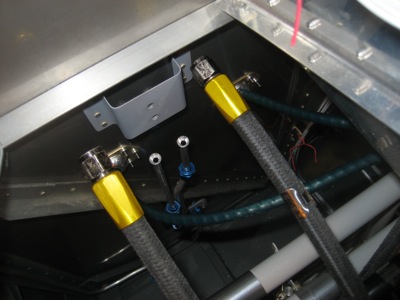

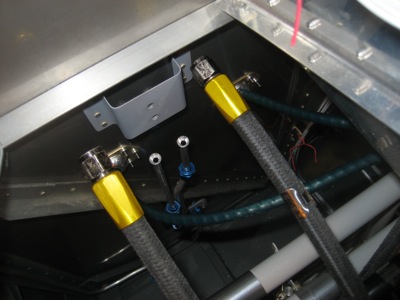

The brake cable is secured with about a million adel clamps. The first one is screwed to a little flange and nutplate that I riveted to the bottom of the radio stack reinforcement angle that goes along the bottom of the subpanel.

From there, it goes forward to the bottom of the avionics shelf and turns left…

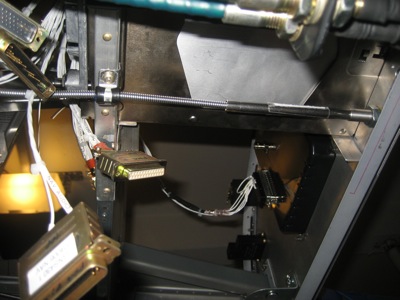

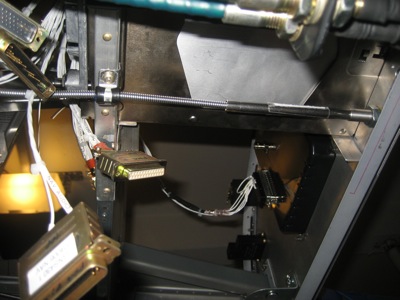

Another clamp helps it turn the corner and head upwards. It's actually not this wavy-looking in real life, it's just how it looks in a macro photo.

One more clamp sends the cable straight up, where it does a 180 and points downward to the brake valve. A final adel clamp holds the cable end, and is attached to a sloping piece of angle I ran between the F-695 fuselage gusset to the left subpanel rib.

All this elaborate routing is required because of the way the valve lever operates. When the parking brake knob is pushed all the way in, the lever is down and the brake valve is open – in other words, the brakes will work normally.

When the knob is pulled out a couple inches, like this…

…the lever is up and the brake valve is closed, trapping pressure in the brake lines and keeping the brakes applied even after you let up on the pedals. Note that the end of the cable sheath provides a positive stop to keep the lever from going over center… I'll probably replace this cushioned adel clamp with one of these later on, just so the cable can't slip.

This is all pretty simple, but like many things it's not in the plans and you're left to your own devices. The whole panel area is full of situations like this – in fact, I've been so busy doing my own thing with wiring and whatnot that I don't think I've looked at the plans for many months.