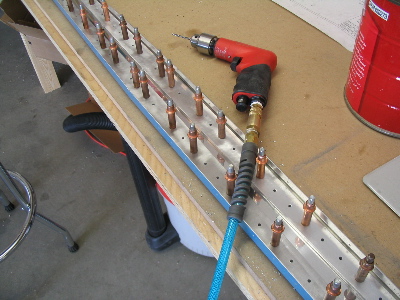

Occasionally, living in Kansas has its advantages – like the way I can order something from the Yard Store in Wichita and it gets here the next business day for like six bucks. Here's the new (rebuilt) rivet squeezer I received today:

It is a clone of the Chicago Pneumatic CP-214, but I don't know who actually made this one. It looks like it was built when FDR was president and has obviously seen a lot of use, but it still works great. Those 1/8" AD4 rivets I was having trouble squeezing by hand are no problem for this guy. In fact, a typical work session with the pneumatic squeezer goes something like this:

Me: Here is a rivet that needs to be squeezed.

CP-214: DESTROY!!!

You get the idea. The folks who say this is the most useful riveting tool they've ever bought are speaking the truth.

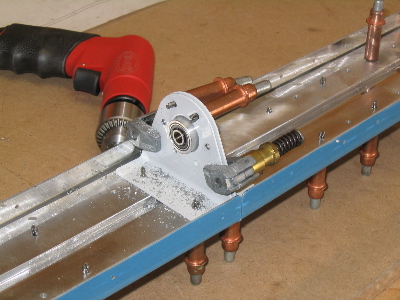

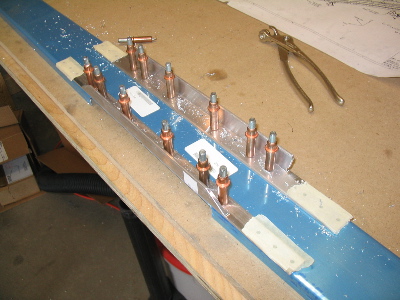

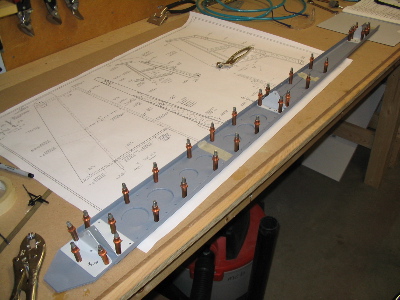

Here I've set the rivets in the center elevator bearing assembly I was working on the other day:

…and then drilled the bolt holes that will attach it to the HS spar:

Then I switched back to the vertical stabilizer spar, seen here resting in the grass after receiving a little primer touch-up:

Although it looks okay in the photo, I'm not totally happy with the way it turned out. For one thing, I foolishly damaged some holes by trying to drill out three rivets with the wrong size drill bit. Must double-check drill size next time. Those holes will have to be filled with bolts, probably, so there goes the weight savings I picked up by cutting the optional lightening holes.

The other thing I don't like about the VS spar is that I oriented the rivets so the manufactured head is on the forward (internal) side and the shop head is aft (outside). While this is a purely cosmetic issue, it bothers me that I didn't think about which way I was going to put the rivets in so the pretty side would be out. Yes, this is extremely picky, but I am considering chalking this one up to practice and ordering new parts to build a replacement VS spar with the lessons I learned on this one. Stay tuned…