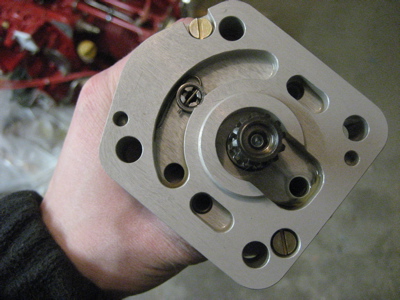

This is the Precision Airmotive RSA-5 fuel injection servo. I need to get this guy bolted onto the airplane, but it didn't come with any instructions – so I don't know, for example, if I need a gasket between the servo and the oil sump, or what. I sent an email to Mattituck.

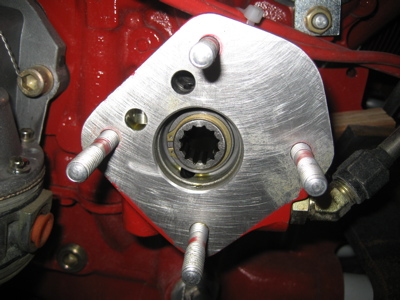

Van's makes a pretty well-done little kit that contains a bellcrank for connecting the mixture cable to the fuel servo, and a series of little brackets for anchoring the control cables to the engine. I removed two of the case bolts and attached the bellcrank bracket to the oil sump, like so:

The mixture cable bracket attaches via another pair of case studs, underneath the #4 cylinder. These nuts all have lockwashers under them.

The throttle cable bracket bolts to a threaded boss on the bottom of the oil sump. I safety-wired the bolt heads:

Those coarse-thread bolts didn't come drilled, so I had to use my handy bolt-head-drilling jig to do it myself:

Here we go, two drilled-head, coarse-thread bolts:

I attached the engine-driven fuel pump's inlet fitting:

…and the outlet fitting, with restrictor fitting to feed the fuel pressure transducer: