Since I need to wait for replacement ribs to continue with the elevators, and I got my pneumatic squeezer back from being rebuilt at Clear Air Tools, I switched back to the rudder. Here the skeleton is coming together:

I used solid rivets to attach the rudder brace to the bottom rib, but I wasn't able to get any of my squeezer yokes inside the brace in order to squash the horn-to-brace rivets, so I used the optional LP4-3 blind rivets there. I could probably have used solid rivets if I'd ground down the top corner of my longeron yoke, but who cares.

The rudder counterweight is installed in its home with nuts and screws. I wonder why this weight is pre-drilled but the elevator ones aren't…?

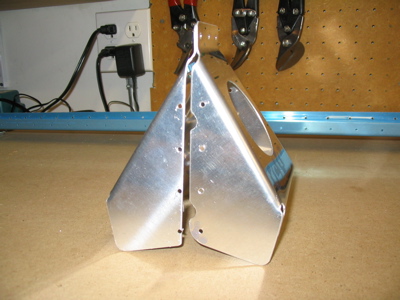

Here the skins have been riveted to the spar.

Next step is the trailing edge, for which I obtained a big piece of 1/8" aluminum angle from the aviation department at Ace Hardware. Clamped to the rudder trailing edge, match-drilled, and held with a cleco in every hole, it will serve to keep the trailing edge perfectly straight while I glue it together and then rivet it.

But that will have to wait for another night since Mary wants to take me for walkies in the park.