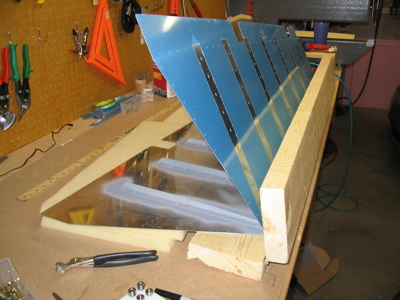

Tonight I made a homebrew bending brake out of some 2×6 lumber and some door hinges, and used it to bend the elevator skins to their final shape.

When I had each one bent as far as it'd go with the bending brake, the open end of the skin was still bobbing in the air about an inch above the spar. Following the advice of those who've gone before me, I used hand seamers (cushioned with duct tape to avoid scratching up the skin) to gently squish along the trailing edge until the skin was resting on the spar.

I was a little worried about this whole process, but it turned out great and was a snap. Next stop looks like deburring and straightening a lot of ribs, so I think I'll quit while I'm ahead.