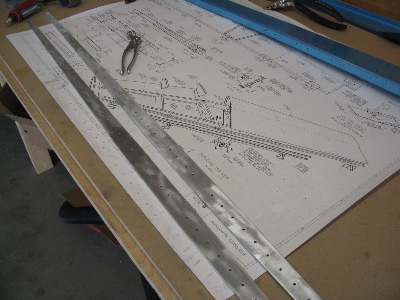

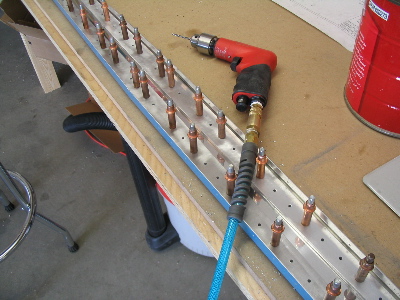

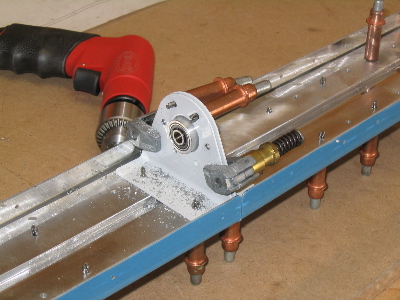

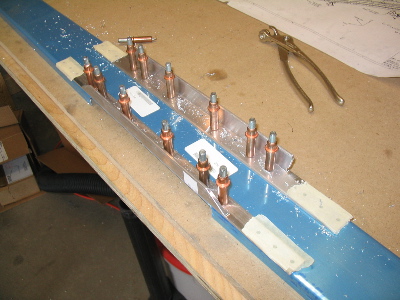

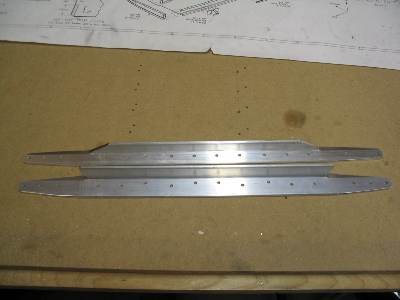

Hey, where'd this airplane-piece-shaped thing come from? I temporarily clecoed the middle and end ribs and front/rear spars of the horizontal stabilizer together to check the bends in HS-710/714 (front spar reinforcements) and HS-702 (front spar). Everything looked good so I drilled the reinforcements to the spars. Not shown are the steps of trimming the inboard flanges of each half of HS-702 to make room for the reinforcement angles, and deburring/straightening/fluting the ribs.

Actually here is a photo of the rib fluting crew hard at work:

Marked and cut the relief notches in the HS-404 inner nose ribs to make room for the reinforcement angles here as well. Had to stop using the air tools since it was getting late and I didn't want to annoy the neighbors, so these will be deburred tomorrow along with their cousins.