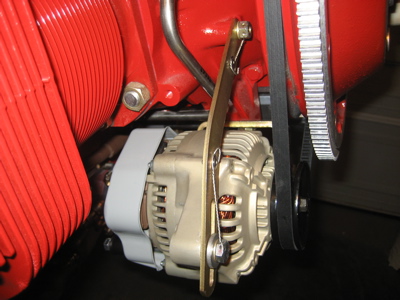

There's a bolt at either end of the alternator tension arm, both of which need to be safetied. Some folks use one long length of safety wire between the two bolts, but that seems like it would be a pain when the belt inevitably wears out (since you need to loosen the bottom bolt to replace the belt). I also didn't want to just loop safety wire around the arm itself, since it would eventually vibrate and dig a groove into the steel.

So, I came up with what I think is a clever way of safetying the two bolts… first I drilled a pair of #30 holes in the meaty part of the arm:

Then I grabbed some #4 steel tinnerman washers and 1/8" steel pop rivets:

When riveted to the arm, the washer sits up above the surface just the right height to capture a loop of safety wire. The wire then bears on the steel pop rivet stem instead of wearing a groove in the arm.

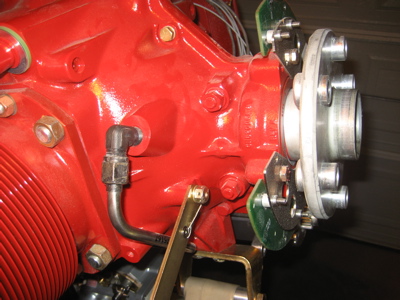

With the ring gear removed, it's pretty easy to safety the upper bolt.

After putting on the belt and adjusting the tension, the lower bolt gets torqued and safetied in the same manner:

For future reference, the belt that seems to fit the best is a Gates 7360:

I tried a 7355 and it did fit, but it was very tough to install. I'll use the slightly longer belt unless I end up having clearance problems between the alternator and cowl.