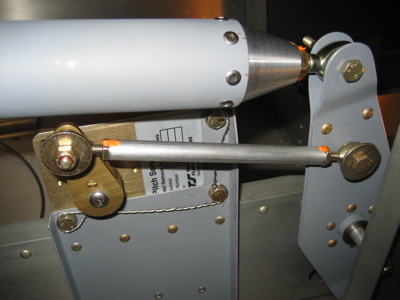

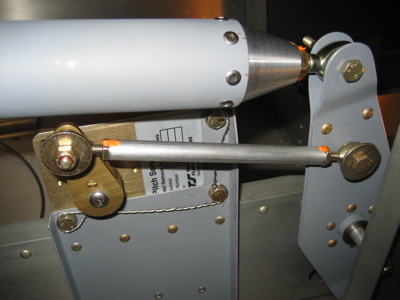

I spent most of the day studying at the library, but I got a few things done on the plane this evening. I safetied the autopilot servo mounting bolts, double checked the aft elevator pushrod length, and torqued a bunch of nuts in the area of the elevator bellcrank. Doing the safety wire took a long time – I always seem to need multiple tries to get safety wire put on right.

If you look closely, you can see the washer that I put between the two halves of the bellcrank, where the autopilot servo's pushrod pivot bolt goes through. If you don't do this, you can't properly torque the nut because the two halves of the bellcrank just smoosh together when you tighten it. A set of washer wrenches is invaluable for little tasks like this. Or, if you haven't built your bellcrank yet, make your F-635B spacer large enough to fill the space where the servo's bolt goes through.

Then I reinstalled the fuel vent lines and torqued the fittings through the fuselage sides. I didn't install the vent fittings on the belly yet, as I'm waiting on some brass screen material to arrive first.

This photo is a reminder to myself that I need to drill out the nutplates on the seatbelt attach brackets and replace them with the dimpled kind, since I'm using countersunk screws wherever possible on the cockpit floors.