Frustratingly, during the final reassembly and checkout prior to first flight, my transponder suddenly quit working:

I discovered that the fuse had blown, and furthermore that the power wire to the transponder was shorted to ground somewhere downstream of the fuse block on the subpanel. I wanted to rule out a problem with the unit itself, so I went to the trouble of pulling up the baggage floor and removing the transponder from its rack – a process which also required removing the lower-aft baggage bulkhead. Sure enough, the transponder tested okay on the bench, and none of the wiring aft of the rear spar looked like it had chafed on anything:

I was hoping the problem wasn't in the center tunnel, as all the wiring that runs through that area is really, really difficult to access. Instead I had a hunch the issue was forward of the spar, so to be able to inspect the wiring I pulled the whole fuel pump/filter/valve assembly:

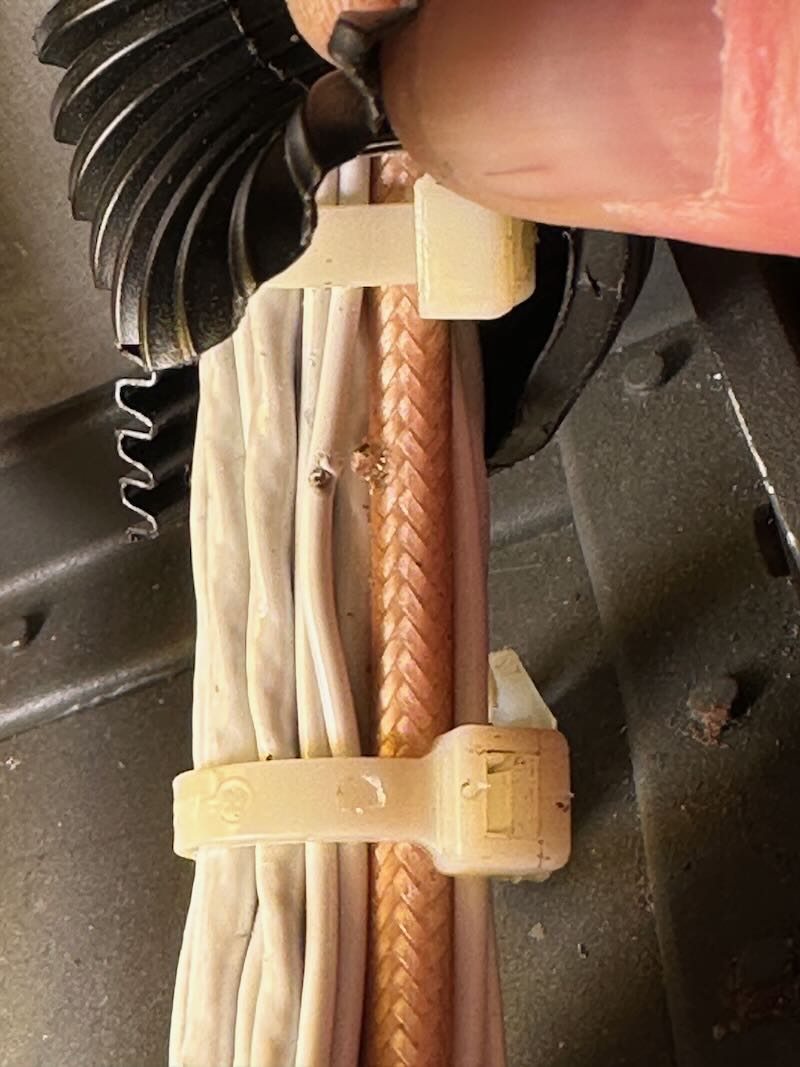

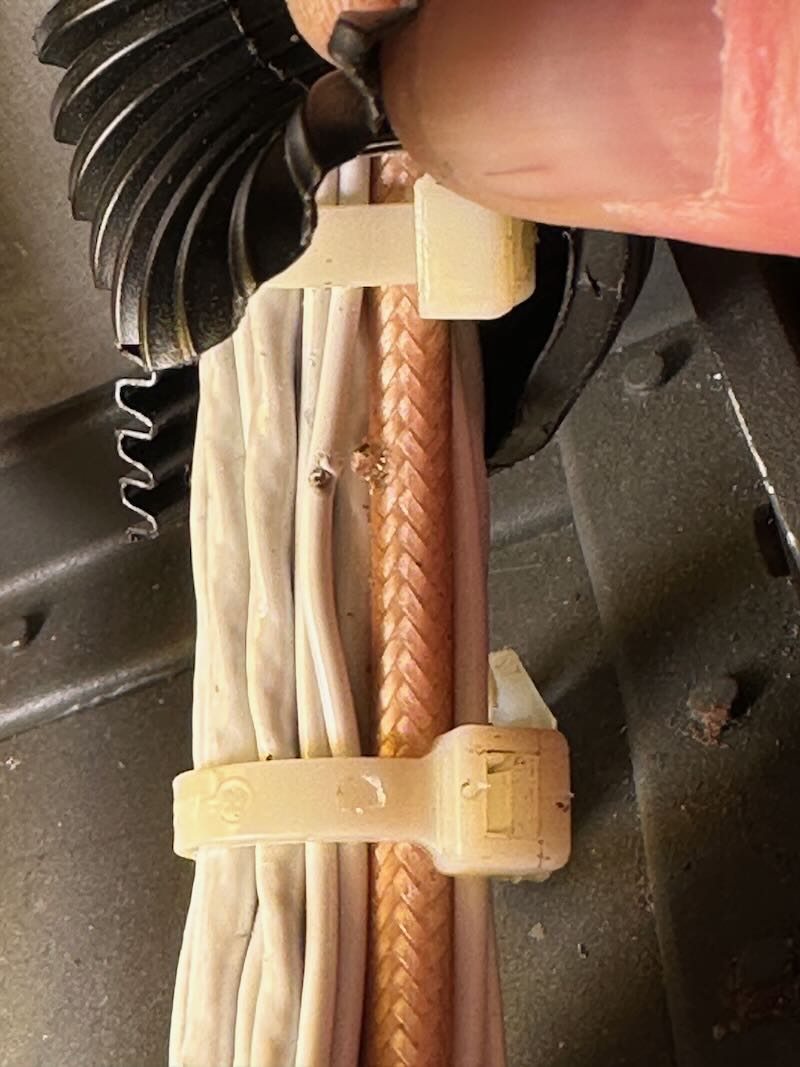

None of the wires normally hidden underneath the fuel plumbing looked suspect, so I removed the forward cabin cover, and that's where I found the culprit. Way up by the firewall, one of the screws securing the F-982E access plate to the F-782C center cabin cover had penetrated a wire bundle:

The reason I suspected the problem would be in this area is that I hadn't previously installed the center cabin cover for years, so it was the only new variable that was likely to have contributed to the sudden appearance of electrical issues. Sure enough, the offending screw chewed up the power wire to the transponder, and also chafed through the outer insulation jacket on an adjacent antenna cable, creating an intermittent short circuit:

This was technically a simple repair: I just spliced the power wire and fixed the coax insulation with some silicone tape. The difficult part was actually getting my hands and eyes on the damaged wires, since they are way, way up in the front of the footwell. I also didn't get a picture of the finished repair, since I couldn't reach my phone while stuck with my head under the panel. But after fixing the wiring and replacing the fuse, the transponder is once again working:

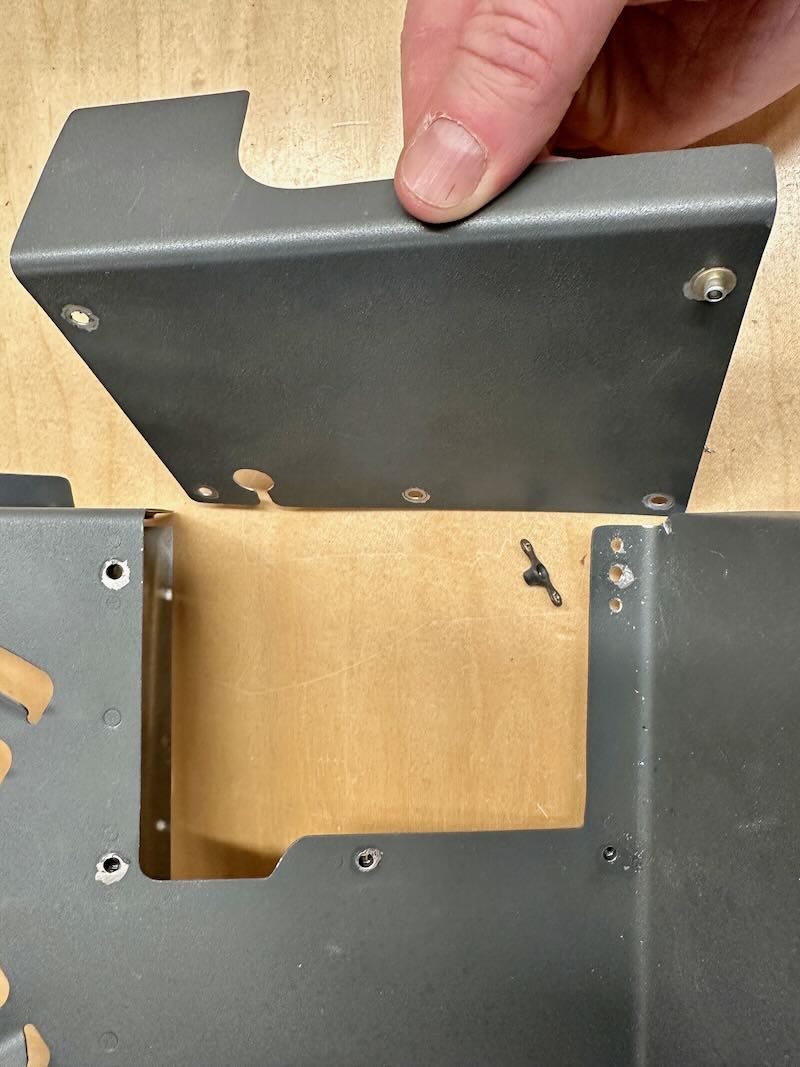

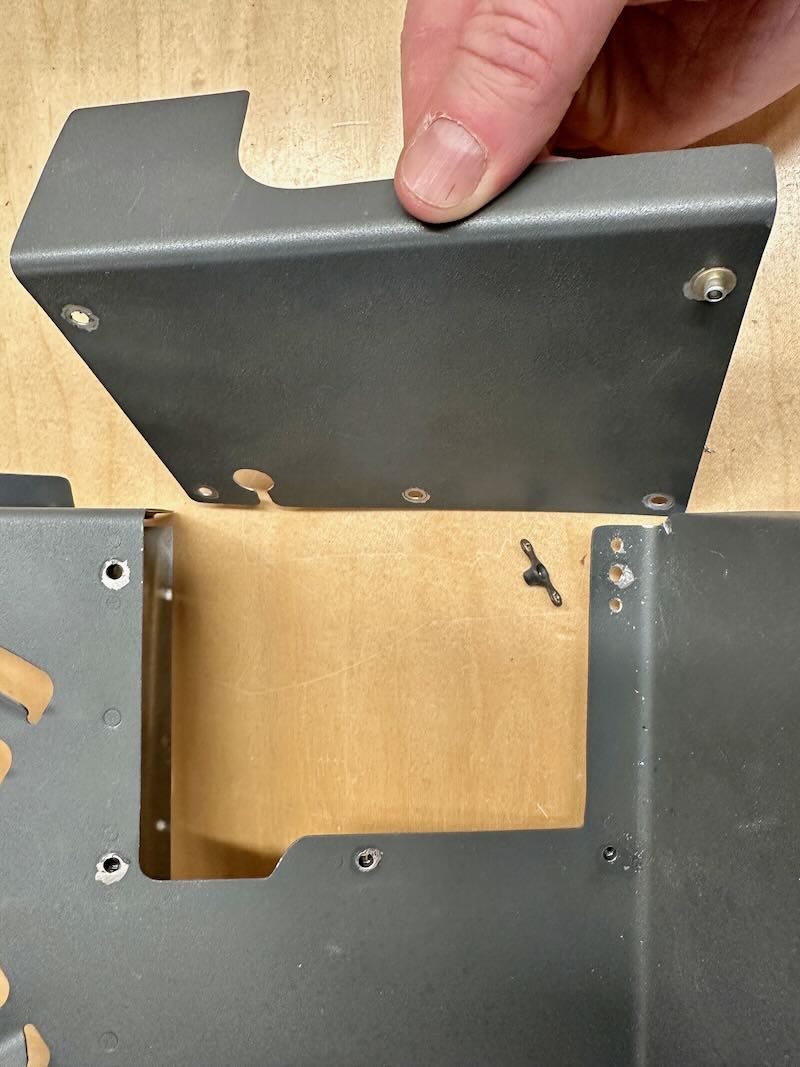

To prevent this from happening again, I simply deleted the nutplate from the offending hole, and filled the hole in the access plate with a rivet to make sure I'm not tempted to stick a screw in there in the future. This purely cosmetic little plate will be more than secure enough with only four out of five screws present:

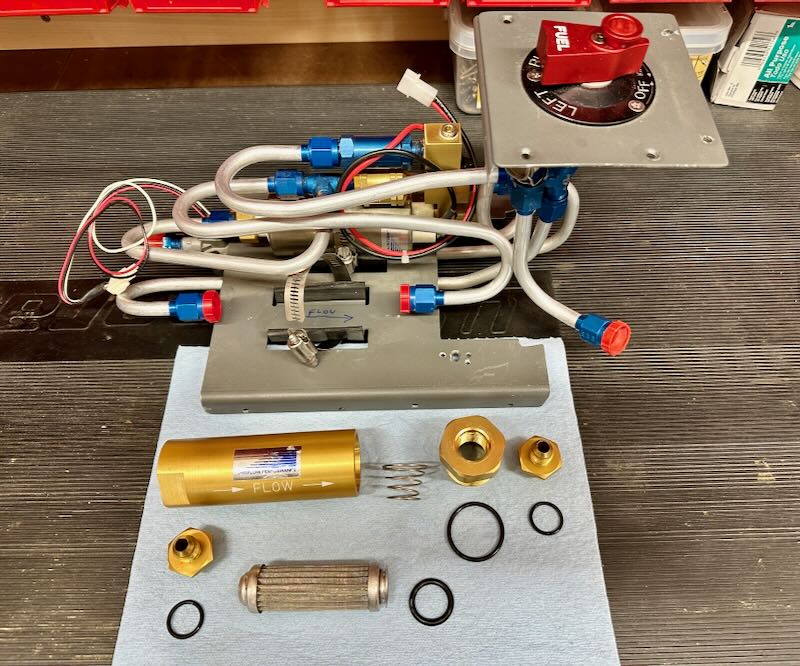

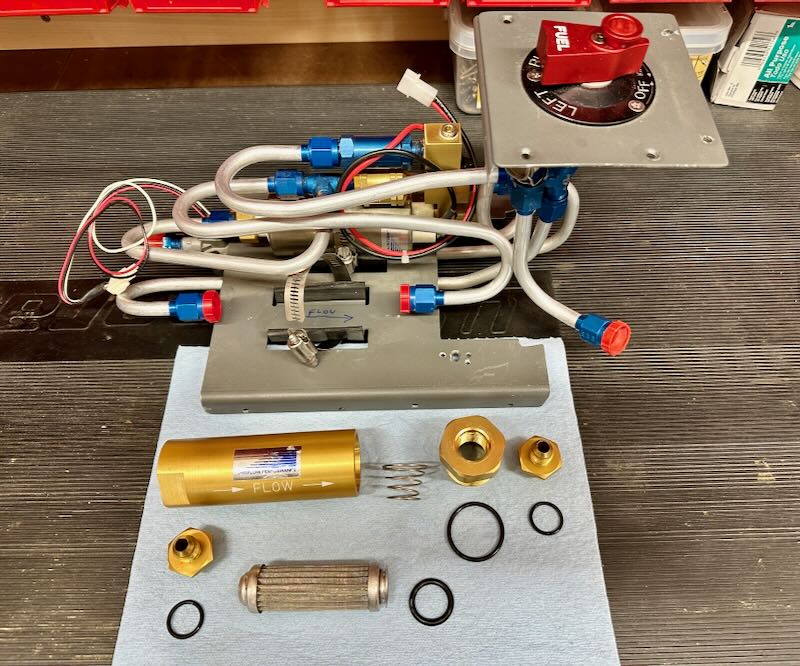

While I had all the fuel plumbing out of the airplane, I decided to service the fuel filter and see if it had picked up any debris from inside the tanks. There's no good way to do this without spilling a bunch of fuel, but at least on the bench it's easier to clean up. I inspected the filter element – nothing of note so far – and cleaned it with mineral spirits. The o-rings still seem to be holding up, so I just lubricated and reinstalled them:

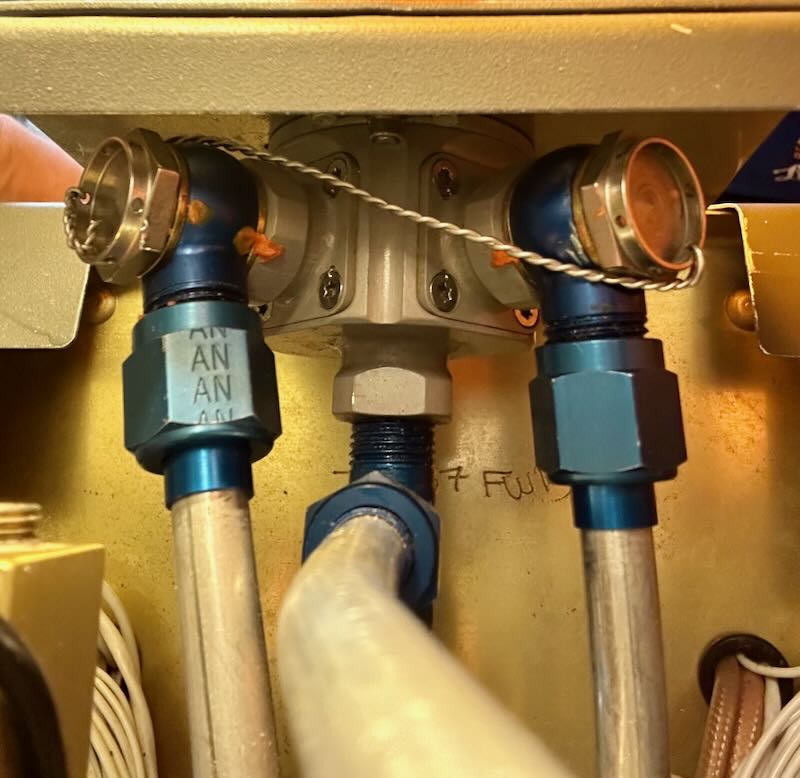

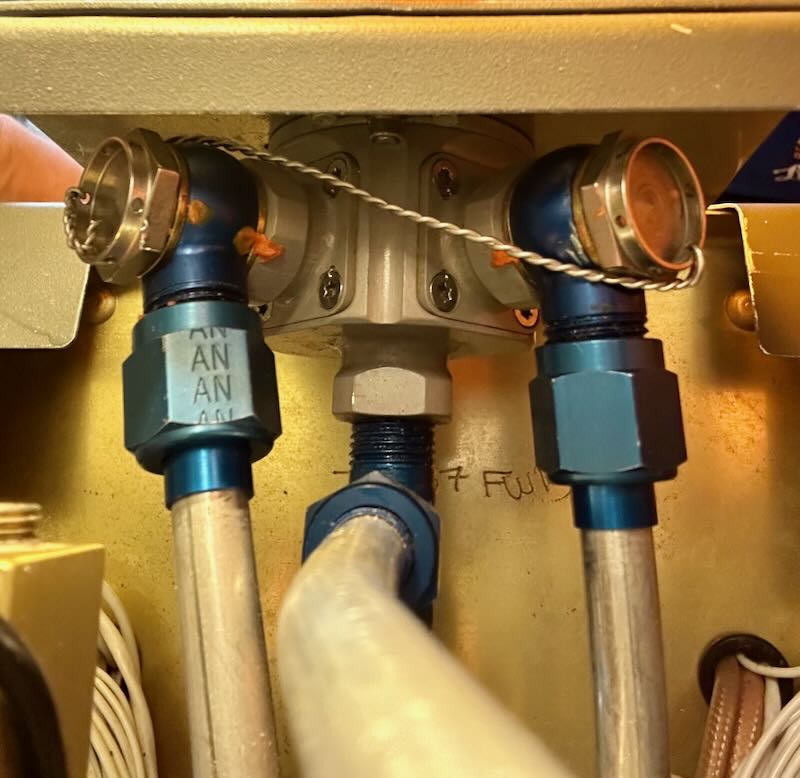

While putting the fuel system back together, I also took the opportunity to retorque the banjo fittings on the fuel selector, and improve the safety wire that secures them. The photo makes it look slack, but in real life it's plenty tight. I don't know why I didn't think of this simpler method before:

Finally, after many days of fighting with it, I got everything put back the way it was a couple weeks ago: